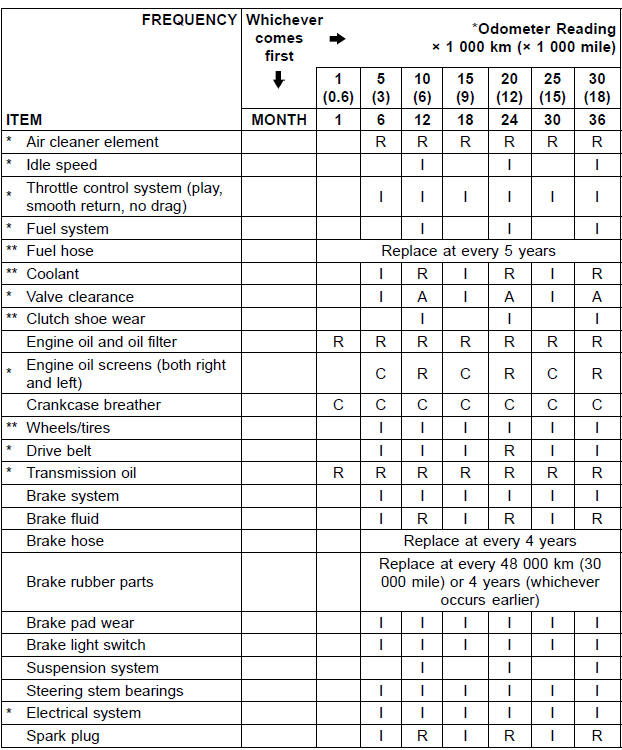

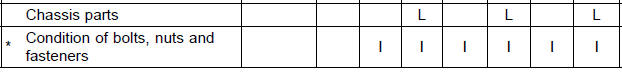

Kawasaki J300 - Service manual > Periodic Maintenance Chart

Kawasaki J300 - Service manual > Periodic Maintenance Chart

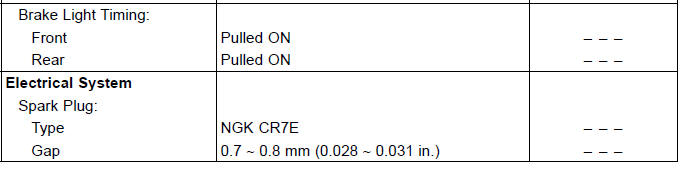

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition.

The initial maintenance is vitally important and must not be neglected.

I: Inspection and Clean, Adjust, Lubricate or Replace if necessary

C: Clean

A: Adjust

R: Replace

L: Lubricate

*: Should be serviced by your Kawasaki dealer, unless you have the proper

tools, service data and are technically qualified.

**: In the interest of safety, we recommend these items be serviced only by your

Kawasaki dealer.

Kawasaki recommends that your Kawasaki dealer road test your scooter after each periodic maintenance service is completed.

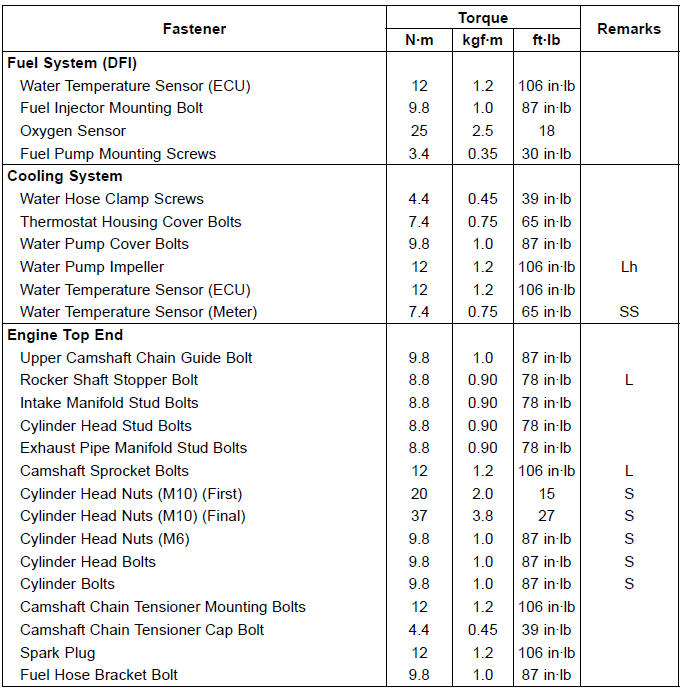

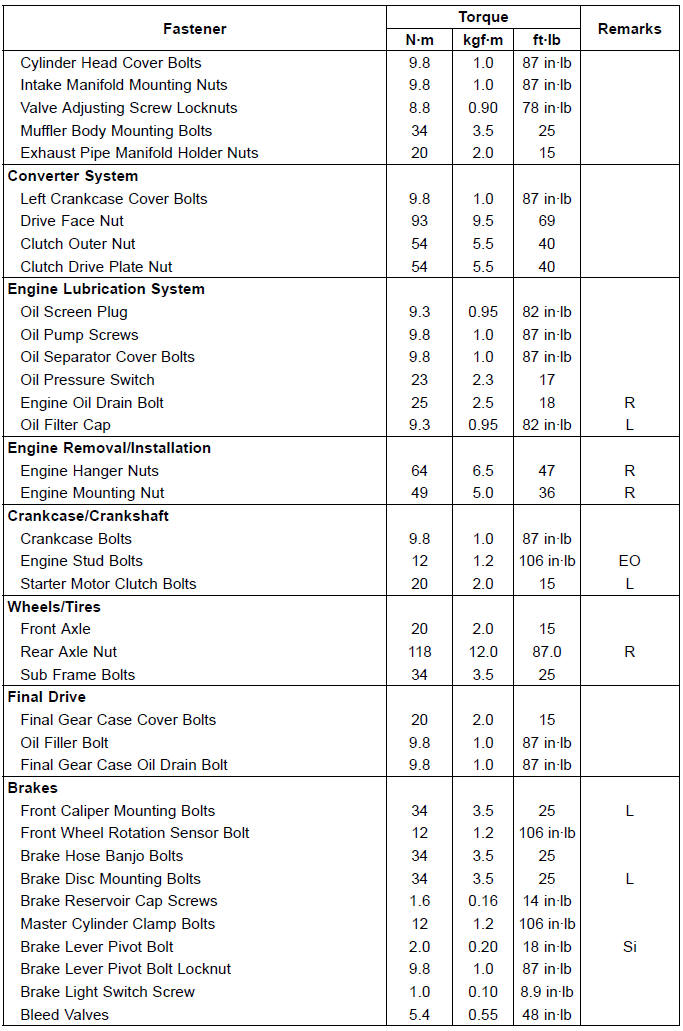

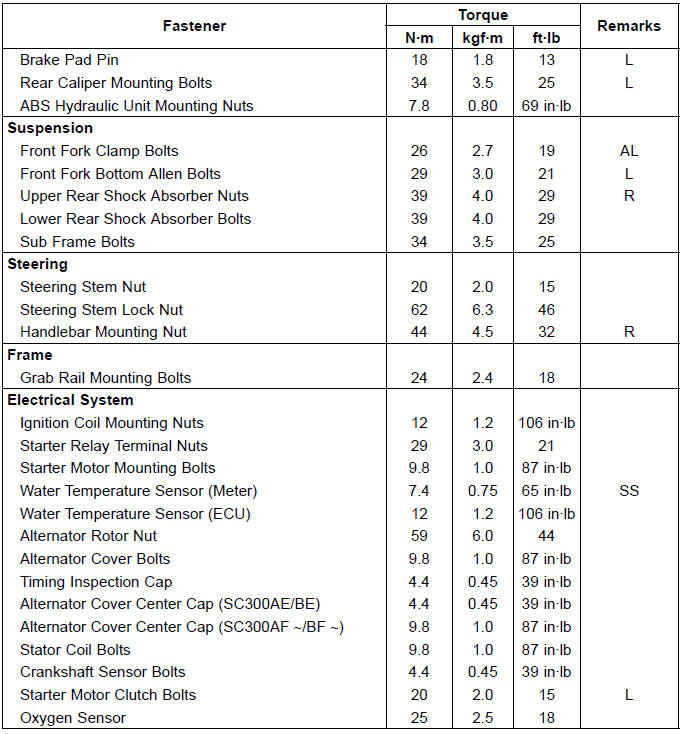

Torque and Locking Agent

Tighten all bolts and nuts to the proper torque using an accurate torque wrench. If insufficiently tightened, a bolt or nut may become damaged, strip an internal thread, or break and then fall out. The following table lists the tightening torque for the major bolts and nuts, and the parts requiring use of a non-permanent locking agent or silicone grease etc. All of the values are for use with dry solvent - cleaned threads unless otherwise indicated.

When checking the tightening torque of the bolts and nuts, first loosen the bolt or nut by half a turn and then tighten to specified torque.

Letters used in the "Remarks" column mean:

AL: Tighten the two clamp bolts alternately two times to ensure even

tightening torque.

EO: Apply engine oil.

G: Apply grease.

L: Apply a non-permanent locking agent.

Lh: Left-hand Threads.

R: Replacement Parts.

S: Follow the specified tightening sequence.

Si: Apply silicone grease.

SS: Apply silicone sealant.

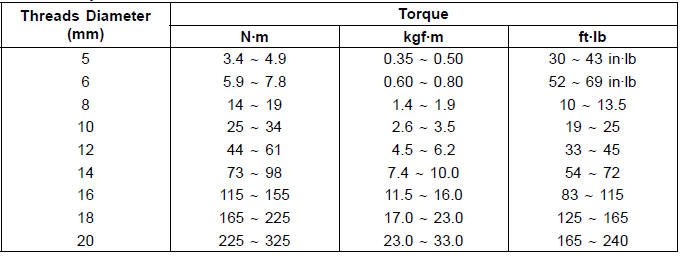

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solvent-cleaned threads.

Basic Torque for General Fasteners

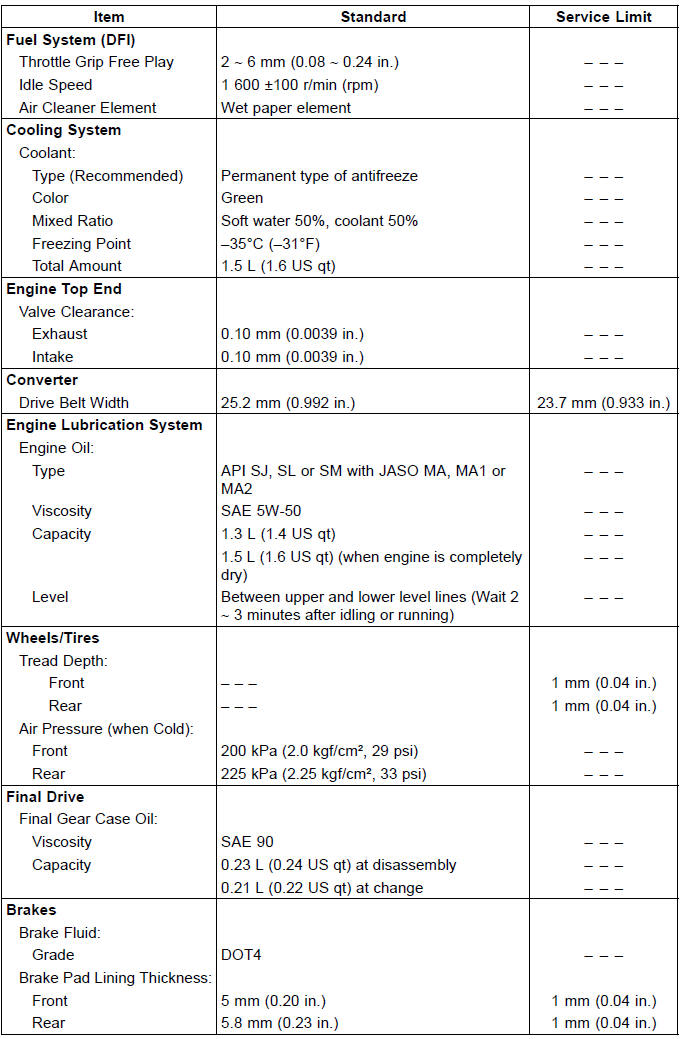

Specifications

Special Tools

Inside Circlip Pliers: 57001-143

Jack: 57001-1238

Steering Stem Nut Wrench: 57001-1100

Flywheel & Pulley Holder: 57001-1605

Valve Adjusting Screw Holder: 57001-1217