Kawasaki J300 - Service manual > Wheels/Tires

Kawasaki J300 - Service manual > Wheels/Tires

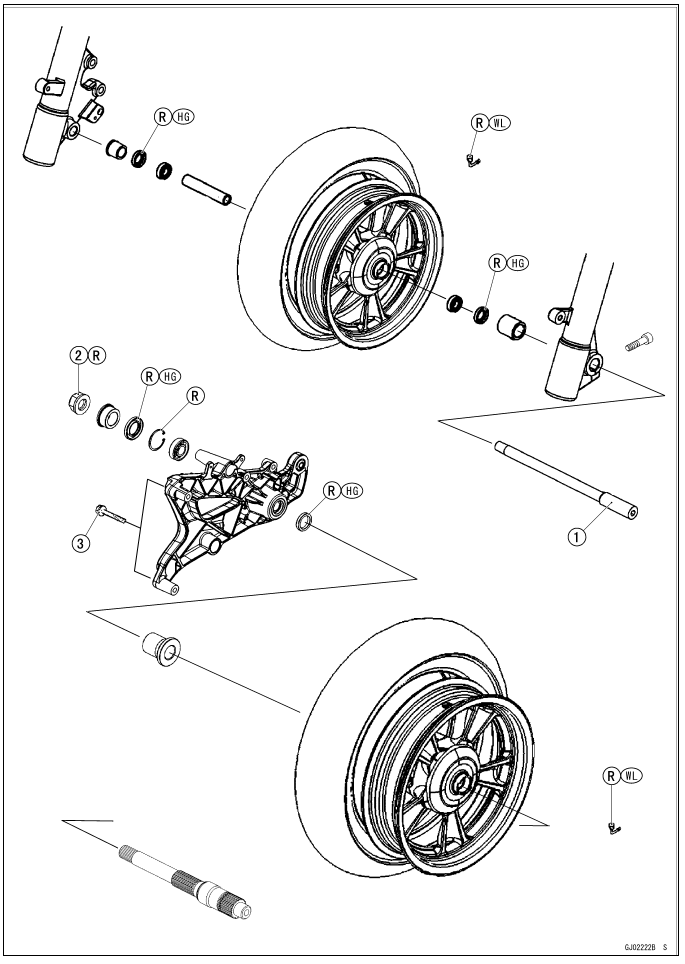

Exploded View

HG: Apply high-temperature grease.

R: Replacement Parts

WL: Apply soap and water solution or rubber lubricant.

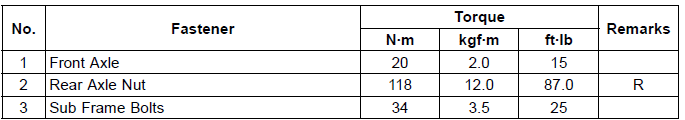

Specifications

WARNING Some replacement tires may adversely affect handling and cause an accident resulting in serious injury or death. To ensure proper handling and stability, use only the recommended standard tires for replacement, inflated to the standard pressure.

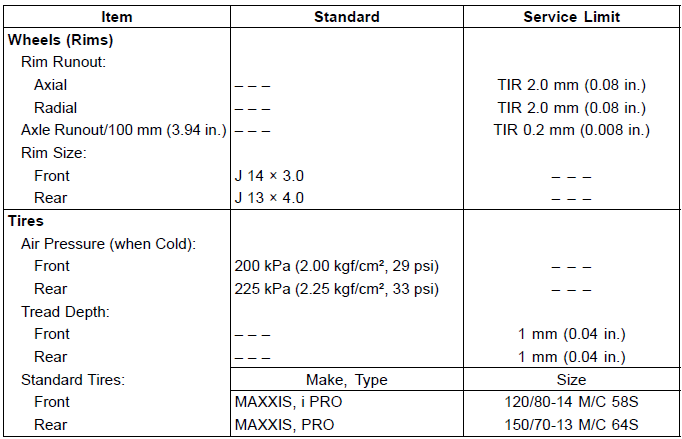

Special Tools

Inside Circlip Pliers: 57001-143

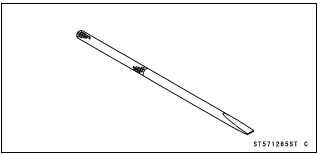

Bearing Remover Shaft,  9:

57001-1265

9:

57001-1265

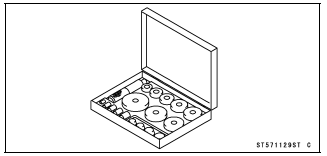

Bearing Driver Set: 57001-1129

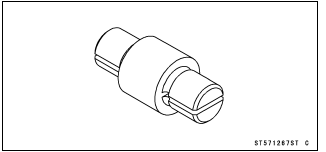

Bearing Remover Head,  15

×

15

×  17:

57001-1267

17:

57001-1267

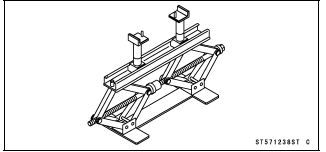

Jack: 57001-1238

Wheels (Rims)

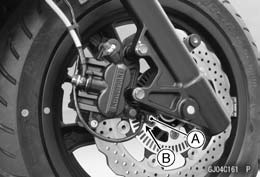

Front Wheel Removal

- Remove:

Front Fender (see Front Fender Removal in the Frame chapter)

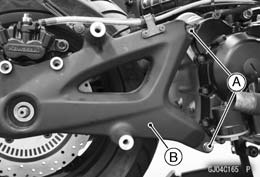

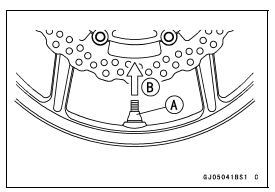

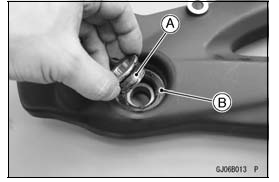

Bolt [A]

Front Wheel Rotation Sensor (Speed Sensor) [B]

- Loosen:

Front Axle Clamp Bolt [A]

Front Axle [B]

- Remove the lower cover (see Lower Cover Removal in the Frame chapter).

- Raise the front wheel off the ground.

Special Tool - Jack: 57001-1238

- Pull out the front axle to the left side and drop the front wheel out of the front forks.

NOTICE Do not lay the wheel on the ground with the disc facing down. This can damage or warp the disc.

Place blocks under the wheel so that the disc does not touch the ground.

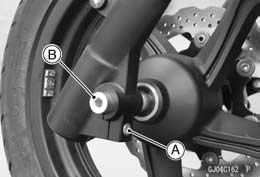

Front Wheel Installation

- Apply high-temperature grease to the grease seal lips.

- Fit the collars [A] on both sides of the hub.

- Install the stepped collar to the right side.

- Insert the front axle from the left side.

- Tighten: Torque - Front Axle: 20 N*m (2.0 kgf*m, 15 ft*lb)

- Before tightening the front axle clamp bolt on the left front fork leg, pump the front fork up and down 4 or 5 times to allow the right front fork leg to seat on the front axle.

NOTE

- Put a block in front of the front wheel to stop moving.

- Tighten the front axle clamp bolt.

- Install the removed parts (see appropriate chapters).

- Check the front brake effectiveness (see Brake Operation Inspection in the Periodic Maintenance chapter).

WARNING After servicing, it takes several applications of the brake lever before the brake pads contact the disc, which could result in increased stopping distance and cause an accident resulting in injury or death.

Do not attempt to ride the motorcycle until a firm brake lever is obtained by pumping the lever until the pads are against the disc.

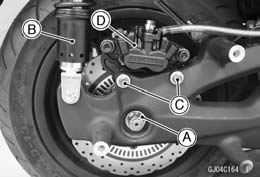

Rear Wheel Removal

- Use the center stand to support the motorcycle upright.

- Remove:

Muffler Body (see Muffler Body Removal in the Engine Top End chapter)

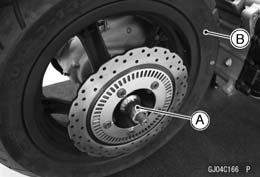

Mud Guard (see Mud Guard Removal in the Frame chapter) - Remove the rear axle nut [A].

NOTE

- When loosening the rear axle nut, hold the rear brake on.

- Remove:

Right Rear Shock Absorber [B] (see Rear Shock Absorber Removal in the Suspension chapter)

Rear Caliper Mounting Bolts [C]

Rear Caliper [D]

- Remove:

Sub Frame Bolts [A]

Sub Frame [B]

- Remove:

Collar [A]

Rear Wheel [B]

Rear Wheel Installation

- Installation is the reverse of removal.

- Replace the rear axle nut with a new one.

- Tighten:

Torque - Sub Frame

Bolts: 34 N*m (3.5 kgf*m, 25 ft*lb)

Rear Axle Nut: 118 N*m (12.0 kgf*m, 87.0 ft*lb) - Install the removed parts (see appropriate chapters).

- Check the rear brake effectiveness (see Brake Operation Inspection in the Periodic Maintenance chapter).

WARNING After servicing, it takes several applications of the brake lever before the brake pads contact the disc, which could result in increased stopping distance and cause an accident resulting in injury or death.

Do not attempt to ride the motorcycle until a firm brake lever is obtained by pumping the lever until the pads are against the disc.

Wheel Inspection

- Remove the lower cover (see Lower Cover Removal in the Frame chapter).

- Raise the front/rear wheel off the ground.

Special Tool - Jack: 57001-1238

- Spin the wheel lightly, and check for roughness or binding.

If roughness or binding is found, replace the following parts.

Hub Bearings (see Hub Bearing Removal/Installation)

Sub Frame Bearing (see Sub Frame Bearing Removal/ Installation)

Final Shaft Bearing (see Final Reduction Bearing Replacement in the Final Drive chapter) - Inspect the wheel for small cracks, dents, bending, or warp.

If there is any damage to the wheel, replace the wheel.

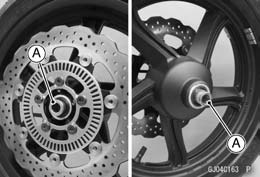

- Remove the wheel, and support it with the tire by the axle or final shaft.

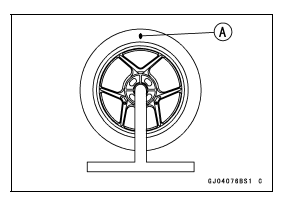

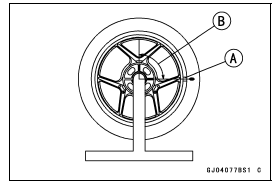

- Measure the rim runout, axial [A] and radial [B], with a dial gauge.

If rim runout exceeds the service limit, check the following.

Hub Bearings/Sub Frame Bearing (see Hub Bearing/ Sub Frame Bearing Inspection)

Bearings of Final Shaft (see Final Gear Case Inspection in the Final Drive chapter)

If the problem is not due to the bearings, replace the wheel.

Rim Runout (with tire installed)

Service Limit:

Axial TIR 2.0 mm (0.08 in.)

Radial TIR 2.0 mm (0.08 in.)

WARNING Damaged wheel parts may fail and cause an accident resulting in serious injury or death. Never attempt to repair a damaged wheel part. If the wheel part is damaged, it must be replaced with a new one.

Front Axle Inspection

- Remove the front axle (see Front Wheel Removal).

- Visually inspect the front axle for damages.

If the axle is damaged or bent, replace it.

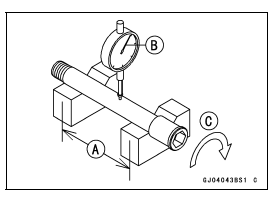

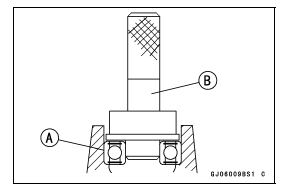

- Place the axle in V blocks that are 100 mm (3.94 in.) [A] apart, and set

a dial gauge [B] on the axle at a point halfway between the blocks. Turn [C]

the axle to measure the runout. The difference between the highest and

lowest dial readings is the amount of runout.

If axle runout exceeds the service limit, replace the axle.

Axle Runout/100 mm (3.94 in.)

Service Limit: TIR 0.2 mm (0.008 in.)

Balance Inspection (Front Wheel Only)

- Remove the front wheel (see Front Wheel Removal).

- Support the wheel so that it can be spun freely.

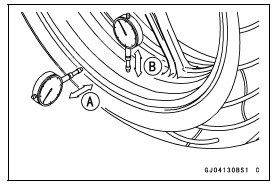

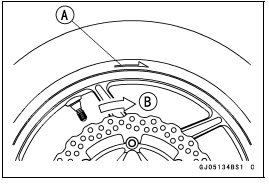

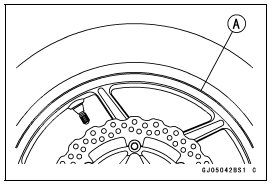

- Spin the wheel lightly, and mark [A] the wheel at the top when the wheel

stops.

- Repeat this procedure several times. If the wheel stops of its own accord in various positions, it is well balanced.

If the wheel always stops in one position, adjust the wheel balance (see Balance Adjustment).

Balance Adjustment (Front Wheel Only)

- If the wheel always stops in one position, provisionally attach a balance weight [A] on the rim at the marking using adhesive tape.

- Rotate the wheel 1/4 turn [B], and see whether or not the wheel stops in

this position. If it does, the correct balance weight is being used.

If the wheel rotates and the weight goes up, replace the weight with the next heavier size. If the wheel rotates and the weight goes down, replace the weight with the next lighter size. Repeat these steps until the wheel remains at rest after being rotated 1/4 turn.

- Rotate the wheel another 1/4 turn and then another 1/4 turn to see if the wheel is correctly balanced.

- Repeat the entire procedure as many times as necessary to achieve correct wheel balance.

- Permanently install the balance weight.

Balance Weight Removal (Front Wheel Only)

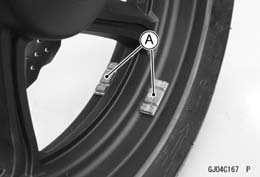

- Remove the balance weights [A].

- Discard the used balance weight.

Balance Weight Installation (Front Wheel Only)

- Using a high flash-point solvent, clean off any oil or dirt that may be balance weight installing area.

- Install the balance weight(s).

WARNING Unbalanced wheels can create an unsafe riding condition. If the balance weight has any play on the rib of the rim, it means it is not installed securely on the rim and it could fly off during riding. Replace the loose balance weight. Do not reuse the used balance weight.

NOTE

- Use the commercially available balance weights. An imbalance of less than 10 grams (0.35 oz.) will not usually affect running stability.

Tires

Air Pressure Inspection/Adjustment

- Refer to the Air Pressure Inspection in the Periodic Maintenance chapter.

Tire Inspection

- Refer to the Wheel/Tire Damage Inspection in the Periodic Maintenance chapter.

Tire Removal

- Remove:

Wheels (see Front/Rear Wheel Removal)

Valve Core (Let out the air) - To maintain wheel balance, mark the valve stem position on the tire with

chalk so that the tire can be reinstalled in the same position.

Chalk Mark or Painted Mark [A]

Valve Stem [B]

Align [C]

- Remove the tire from the rim using a suitable commercially available tire changer. For this model, do not apply any lubricant or solution on tire beads and rim flanges while assembling or removing tire.

NOTE

- The tires cannot be removed with hand tools because they fit the rims too tightly.

Tire Installation

WARNING Mixing tire brands and types can adversely affect handling and cause an accident resulting in injury or death. Always use the same manufacturer's tires on both front and rear wheels.

- Inspect the rim and tire, and replace them if necessary.

- Clean the sealing surfaces of the rim and tire, and smooth the sealing surfaces of the rim with a fine emery cloth if necessary.

- Remove the air valve and discard it.

NOTICE Replace the air valve whenever the tire is replaced.

Do not reuse the air valve.

- Install a new valve in the rim.

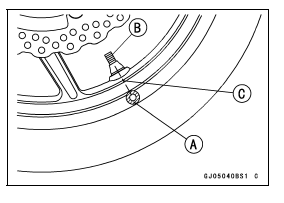

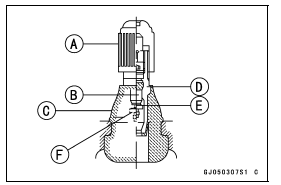

- Remove the valve cap, lubricate the stem seal [A] with a soap and water solution or rubber lubricant, and pull [B] the valve stem through the rim from the inside out until it snaps into place.

NOTICE Do not use engine oil or petroleum distillates to lubricate the stem because they will deteriorate the rubber.

- The air valve is as shown.

Valve Cap [A]

Valve Core [B]

Stem Seal [C]

Valve Stem [D]

Valve Seat [E]

Valve Opened [F]

- Check the tire rotation mark on the front and rear tires and install

them on the rim accordingly.

Tire Rotation Mark [A]

Rotating Direction [B]

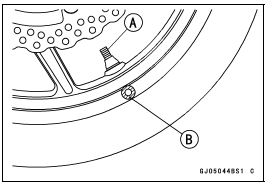

- Position the tire on the rim so that the valve [A] aligns with the tire balance mark [B] (the chalk mark made during removal, or the painted mark on a new tire).

- Install the tire bead over the rim flange using a suitable commercially available tire changer. For this model, do not apply any lubricant or solution on tire beads and rim flanges while assembling or removing tire.

- Center the rim in the tire beads, and inflate the tire with compressed air until the tire beads seat in the sealing surfaces.

WARNING Overinflating a tire can cause it to explode, causing serious injury or death. Be sure to install the valve core whenever inflating the tire, and do not inflate the tire to more than 400 kPa (4.0 kgf/cm², 57 psi).

- Check to see that the rim lines [A] on both sides of the tire sidewalls

are parallel with the rim flanges.

If the rim flanges and tire sidewall rim lines are not parallel, remove the valve core.

- Lubricate the rim flanges and tire beads.

- Install the valve core and inflate the tire again.

- After the tire beads seat in the rim flanges, check for air leakage.

- Inflate the tire slightly above standard inflation.

- Use a soap and water solution or submerge the tire, and check for bubbles that would indicate leakage.

- Adjust the air pressure to the specified pressure (see Air Pressure Inspection in the Periodic Maintenance chapter).

- Install the air valve cap.

- Adjust the wheel balance (see Balance Adjustment).

Tire Repair

Currently two types of repair for tubeless tires have come into wide use. One type is called a temporary (external) repair which can be carried out without removing the tire from the rim, and the other type is called permanent (internal) repair which requires tire removal. It is generally understood that higher running durability is obtained by permanent (internal) repairs than by temporary (external) ones.

Also, permanent (internal) repairs have the advantage of permitting a thorough examination for secondary damage not visible from external inspection of the tire. For these reasons, Kawasaki does not recommend temporary (external) repair. Only appropriate permanent (internal) repairs are recommended. Repair methods may vary slightly from make to make. Follow the repair methods indicated by the manufacturer of the repair tools and materials so that safe results can be obtained.

Hub Bearing

Hub Bearing Removal

- Remove the front wheel (see Front Wheel Removal), and take out the

following.

Collars

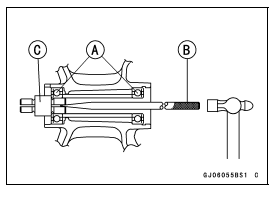

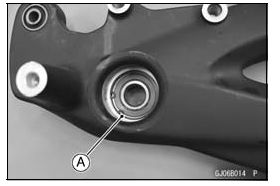

Grease Seals - Use the bearing remover to remove the hub bearings [A].

NOTICE Do not lay the wheel on the ground with the disc facing down. This can damage or warp the disc.

Place blocks under the wheel so that the disc does not touch the ground.

Special Tools -

Bearing Remover Shaft,  9

[B]: 57001-1265

9

[B]: 57001-1265

Bearing Remover Head,  15

×

15

×  17 [C]:

57001- 1267

17 [C]:

57001- 1267

Hub Bearing Installation

- Before installing the hub bearings, blow any dirt or foreign particles out of the hub with compressed air to prevent contamination of the bearings.

- Replace the bearings with new ones.

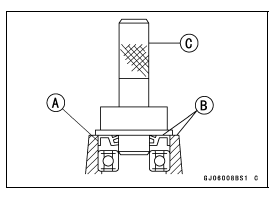

- Install the bearings by using the bearing driver set which does not contact the bearing inner race.

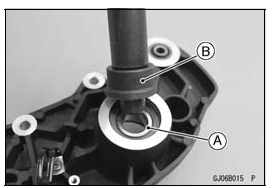

- Press in each right the bearing [A] until they are bottomed.

Special Tool - Bearing Driver Set [B]: 57001-1129

- Replace the grease seals with new ones.

- Press in the grease seals [A] so that the seal surface is flush [B] with

the end of the hole.

- Apply high-temperature grease to the grease seal lips.

Special Tool - Bearing Driver Set [C]: 57001-1129

Sub Frame Bearing Removal

- Remove the sub frame (see Rear Wheel Removal).

- Remove the following parts from the sub frame.

Rear Brake Hose Clamp

Rear Wheel Rotation Sensor (ABS equipped model, see Rear Wheel Rotation Sensor Removal in the Brakes chapter) - Remove:

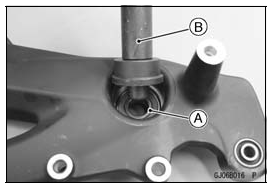

Collar [A]

Grease Seal [B] (Both Sides)

- Remove the circlip [A].

Special Tool - Inside Circlip Pliers: 57001-143

- Remove the bearing [A] by tapping from the wheel side.

Special Tool - Bearing Driver Set [B]: 57001-1129

Sub Frame Bearing Installation

- Before installing the sub frame bearing, blow any dirt or foreign particles out of the hub with compressed air to prevent contamination of the bearing.

- Replace the bearing with a new one.

- Install the bearing by using the bearing driver set which does not contact the bearing inner race.

- Press in the bearing [A] until it is bottomed.

Special Tool - Bearing Driver Set [B]: 57001-1129

- Replace the circlip with a new one.

Special Tool - Inside Circlip Pliers: 57001-143

- Replace the grease seals with new ones.

- Press in the grease seals until they are bottomed.

- Apply high-temperature grease to the grease seal lips.

Special Tool - Bearing Driver Set: 57001-1129

Hub Bearing/Sub Frame Bearing Inspection

Since the bearings are made to extremely close tolerances, the clearance can not normally be measured.

NOTE

- Do not remove any bearings for inspection. If any bearings are removed, they will need to be replaced with new ones.

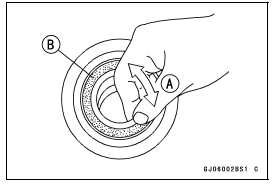

- Turn each bearing in the hub back and forth [A] while checking for plays,

roughness, or binding.

If bearing play, roughness or binding is found, replace the bearing.

- Examine the bearing seal [B] for tears or leakage.

If the seal is torn or is leaking, replace the bearing.

Hub Bearing/Sub Frame Bearing Lubrication

NOTE

- Since the hub bearings are packed with grease and sealed, lubrication is not required.

See also:

Kawasaki J300 - Service manual > Crankcase/Crankshaft

Kawasaki J300 - Service manual > Crankcase/Crankshaft

Exploded View

Kawasaki J300 - Service manual > Final Drive

Kawasaki J300 - Service manual > Final Drive

Exploded View